Waste Heat Recovery System Ppt

Rd d to advance waste heat recovery technologies.

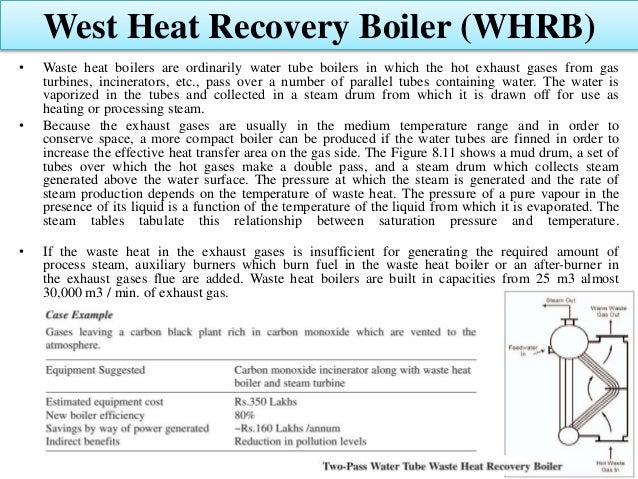

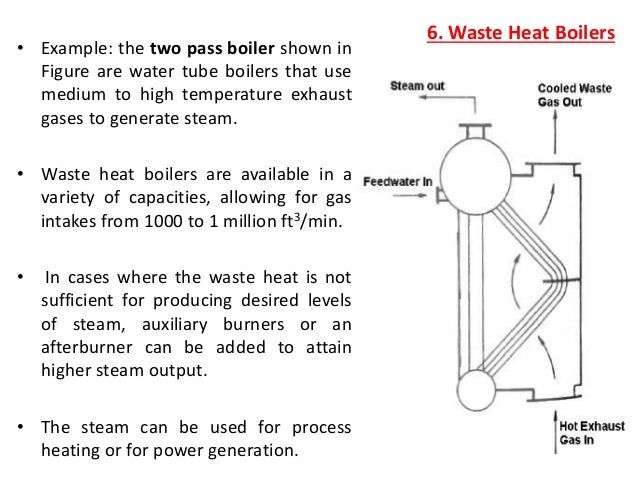

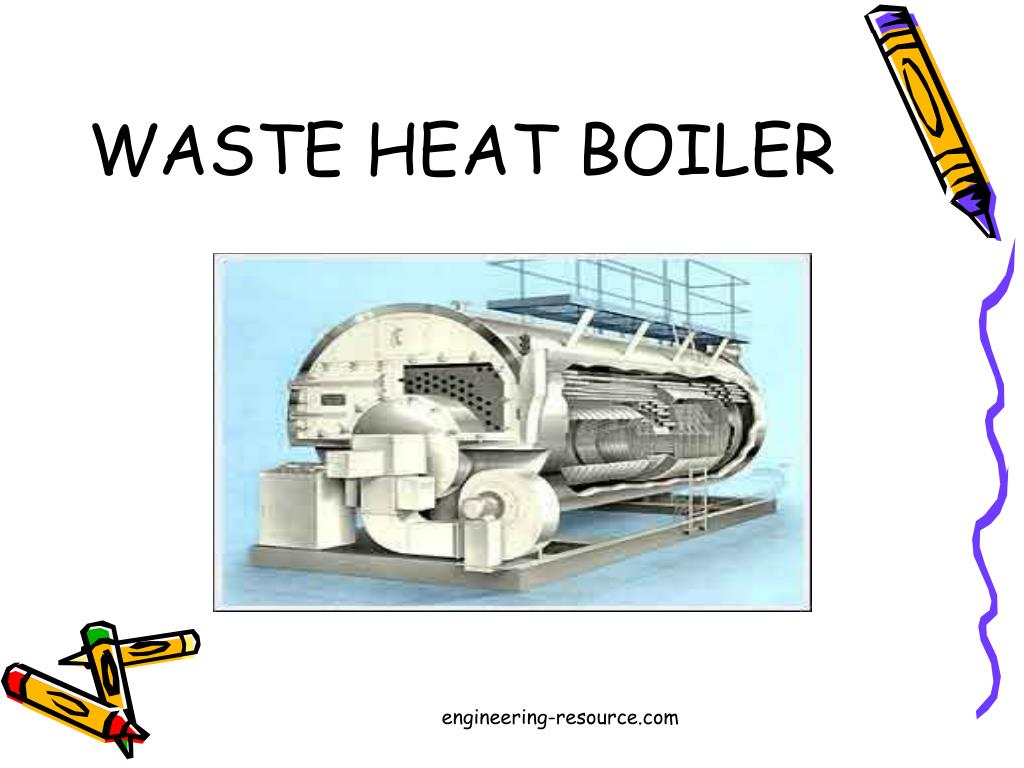

Waste heat recovery system ppt. Academia edu is a platform for academics to share research papers. A waste heat recovery system compris ing both steam and power turbines and combined with utilising scavenge air energy for exhaust boiler feed water heating. Waste heat recovery system 2. The exhaust gas temperature is relatively low after the turbocharger and just high enough for producing the necessary steam for the.

Debajyoti bose upes 2. A heat recovery steam generator hrsg is a type of heat exchanger that captures lost heat from a hot gas stream and then uses it to produce steam energy. Introduction the primary source of waste heat of a main engine is the exhaust gas heat dissipation which accounts for about half of the total waste heat i e. Waste heat recovery system 1.

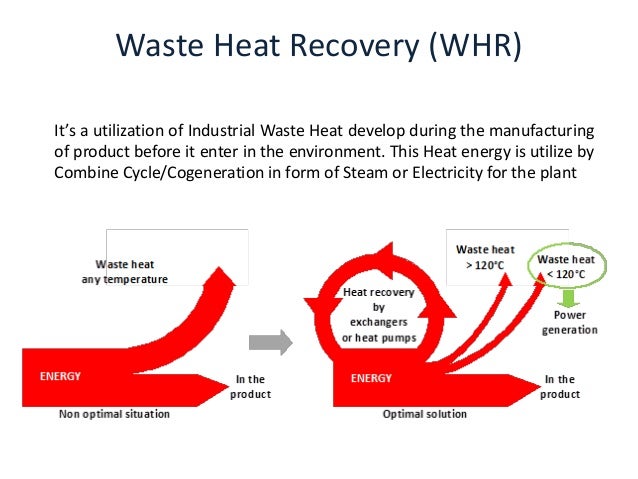

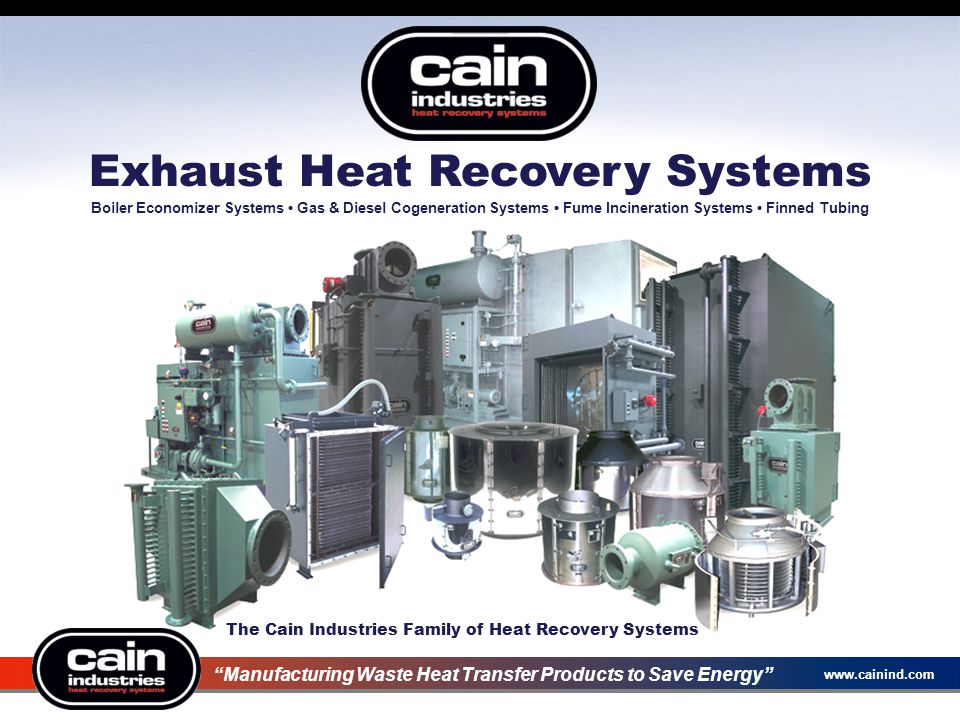

A gas turbine used in energy production a processed gas stream used in a variety of industrial processes or even a waste gas stream. Waste heat recovery options and technologies methods for waste heat recovery include transferring heat between gases and or liquids e g combustion air preheating and boiler feedwater preheating transferring heat to the load entering furnaces generating mechanical and or electrical power or using waste heat with a heat pump for heating or. This paper focuses on one such upcoming system by analysing the efficiency of a thermoelectric generator teg used as a waste heat recovery system in a hybrid electric vehicle hev. This valuable energy can be recovered from many sources.

1 extending the range of existing technologies to enhance their economic feasibility and recovery efficiency and 2 exploring new methods for waste heat recovery especially for unconventional waste heat sources. The first step in planning to install a waste heat recovery system whrs is to work out the net available waste heat that can be used to generate power. An outstanding highlight of this s. Waste heat recovery 1.

This paper describes the technology behind waste heat recovery and the potential for ship owners to lower fuel costs cut emissions and the effect on the eedi of the ship. In a cement plant waste heat is available mainly from kiln exhaust gases and vent air from the clinker cooler. Technology needs are identified in two broad areas.