Thermostatic Steam Trap Working Principle

It utilizes bimetallic strips of dissimilar metals stacked together in pairs.

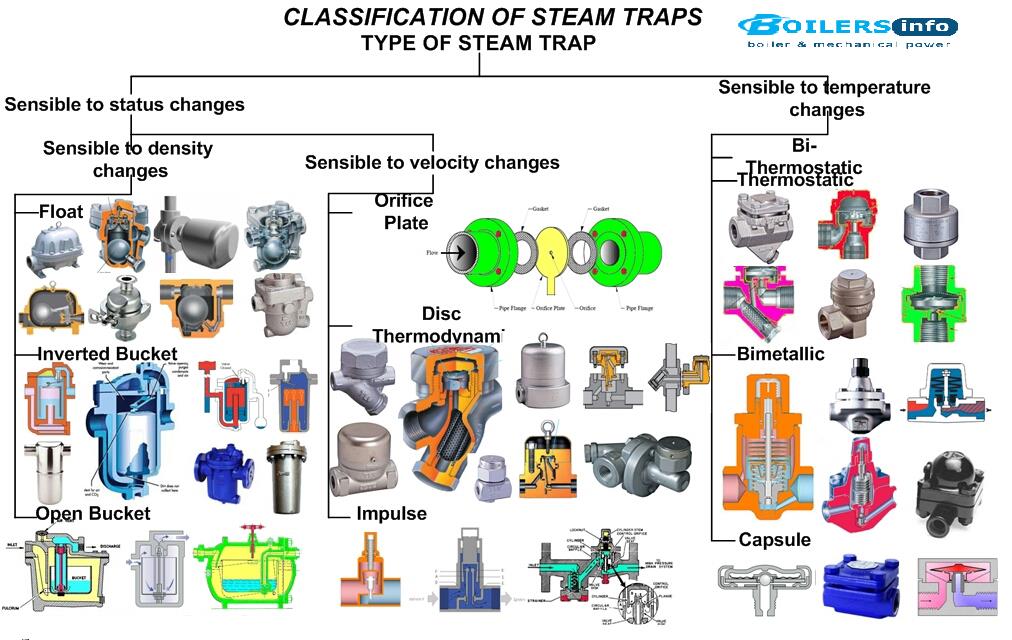

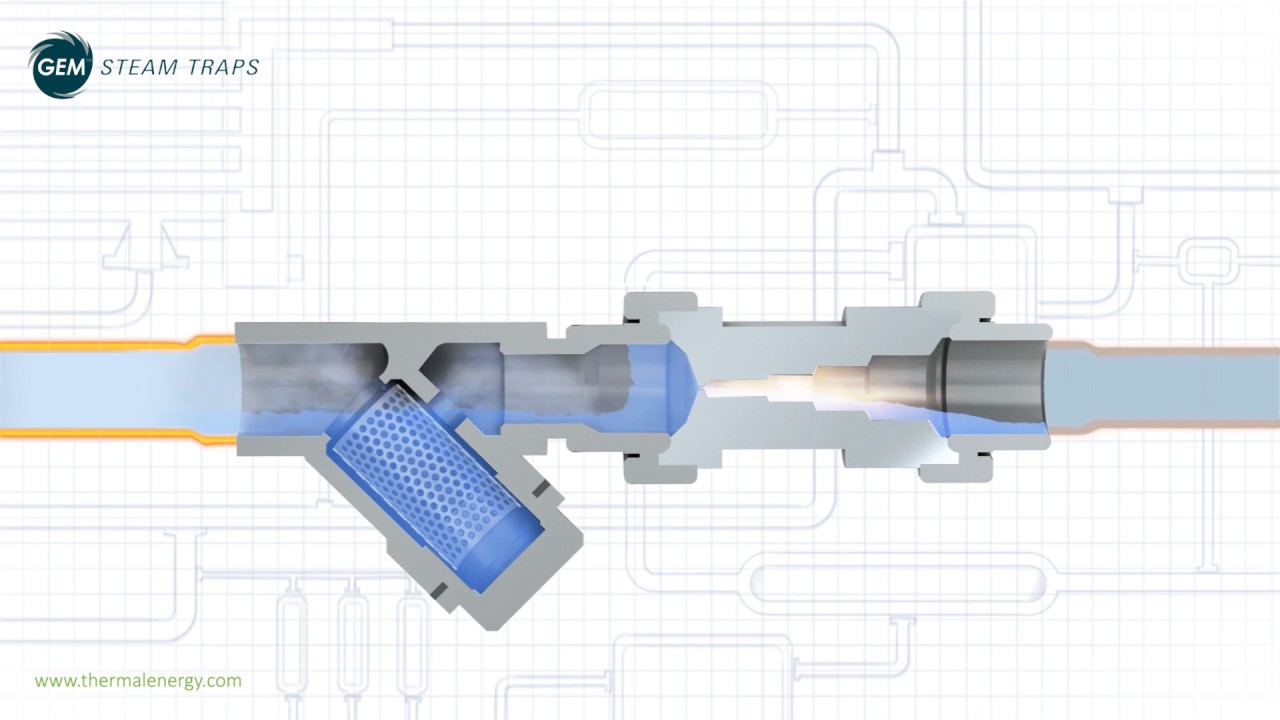

Thermostatic steam trap working principle. A steam trap is a device used to discharge condensates and non condensable gases with a negligible consumption or loss of live steam steam traps are nothing more than automatic valves they open close or modulate automatically. The inverted bucket steam trap is shown in figure 11 3 3. Tlv traps offer three types of temperature sensing materials to detect differences in temperature. Bimetallic trap is classified as temperature operated traps thermostatic trap and it s by and large the most robust design amongst the various types of traps in common use.

In this article we will learn about thermodynamic and vacuum traps. The three important functions of steam traps are. An essential part of the trap is the small air vent hole in the top of the bucket. At star up air will enter the steam trap and will be discharged out through the bleed hole.

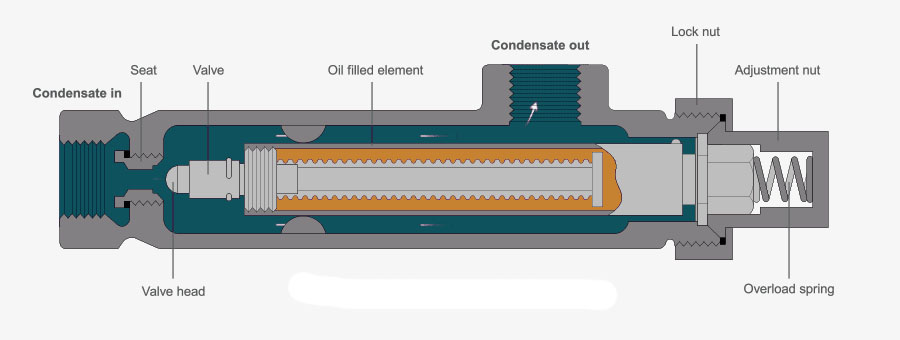

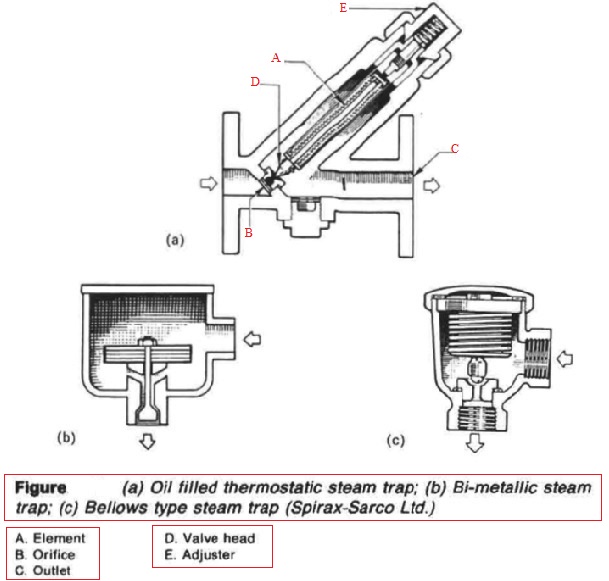

Thermostatic traps operate in response to the surrounding steam temperature. In an oil filled element type steam trap as shown in the figure the element a expands as the temperature of the condensate rises. In the previous article we discussed the basics of a stream trap and learnt about two types of steam traps mechanical and thermostatic steam traps. We will also have a brief look at the maintenance procedures of the same.

Each operates in a different way and is suited to specific types of application. The operation principle for thermostatic steam traps utilizes the temperature difference between steam and condensate. These are mechanical type of steam traps working on the principle of buoyancy. Inverted bucket steam trap.

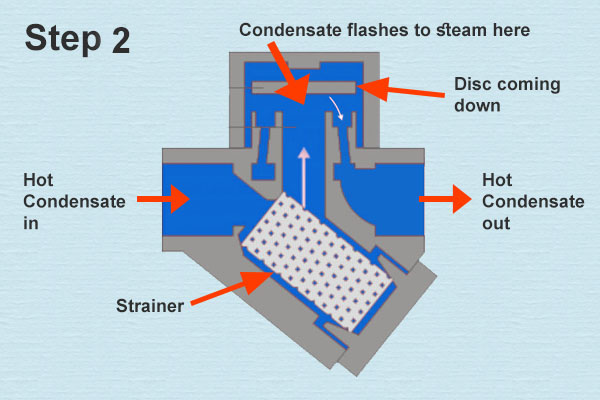

This video explains how a thermodynamic steam trap works. As its name implies the mechanism consists of an inverted bucket which is attached by a lever to a valve. Thermostatic trap also known as the temperature trap uses expansion of a bimetallic strip an oil filled element or a flexible below to activate a valve. Discharge condensate as soon as it is formed unless it is desirable to use the sensible heat of the liquid condensate.

Initially the bucket is resting at the bottom of the steam trap and the valve seat is wide open. The operation and benefits of 3 different types are considered here liquid expansion traps bimetallic and balanced pressure thermostatic traps.